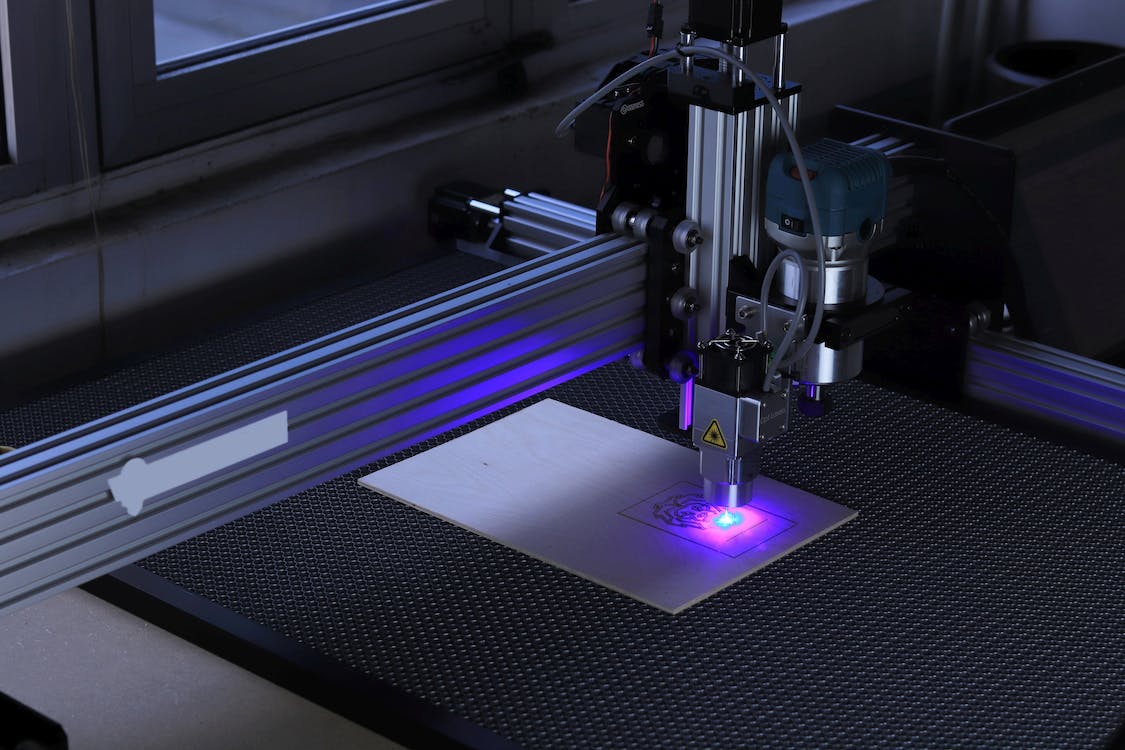

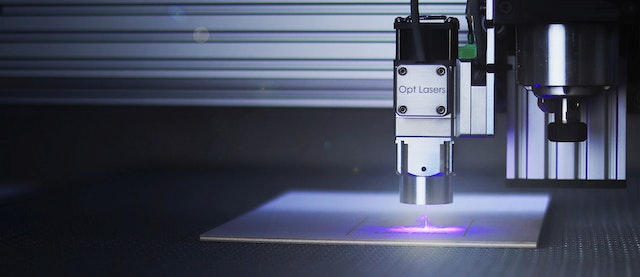

Laser cutting has transformed many industries and its versatility and efficiency in cutting have opened up new possibilities when working with materials. There are certain materials that are commonly used for laser cutting and the article below will explain these in detail.

You can cut metal using a laser cutting machine

Stainless steel is a commonly used material with laser cutting in architecture and automotive industries. You can create intricate designs on the stainless steel while minimising the heat-affected zones. You can also find laser cutting steel applications.

Generally a fibre laser or a CO2 laser will be used depending on the thickness of the material and material type. As the laser head is guided by CNC software, there is very little room for error. You can use laser cutting for cutting steel plates, tubes, sheets and other components and this is very useful in industries like manufacturing, architecture, aerospace and automotive.

The versatility of the laser cutting process accommodates different grades of steel as well. Aluminium, which is a lightweight metal used in electronic, architectural and aircraft applications. This allows you to create a high quality finish. Both thin and thick aluminium sheets can be accommodated but you will need to check with the laser cutting service regarding their limitations.

A material that is known for its strength

Is carbon steel and this is used commonly in construction and manufacturing industries. You can laser cut carbon steel to achieve precision in the cuts. A very high edge quality can be achieved here. An experienced laser cutting technician will help manage the parameters for the laser process to prevent the excessive heat generation which can affect the quality of material.

It can be quite difficult to cut copper and brass because of their high reflective properties. But with an experienced laser cutting service and the right equipment, you can process these materials without difficulty. Copper and brass are used for many decorative applications such as making jewellery. You can also find them used for electrical applications.

You can even cut certain plastic materials with laser cutting machines

One such material that can be accommodated is acrylic which is well-known for its high impact resistance and transparency. You can easily achieve clean and polished edges in acrylic with laser cutting. Many businesses use this for signage as the transparency of acrylic allows for illumination. Polycarbonate is known for its high strength and you can use transparent or translucent polycarbonate for many applications where glass is used.

You can use polycarbonate laser cutting for applications that call for safety and durability such as the creation of eyewear lenses and machine guards. Laser cutting can be used with many organic materials as well. You can create intricate detailing on wood in order to create art installations, manufacture furniture etc.

Leather is another organic material that can be cut this way and it allows you to create decorative patterns and designs on the leather with clean and sealed edges. Other organic materials that can be accommodated are paper and cardboard.